5 minute read

|

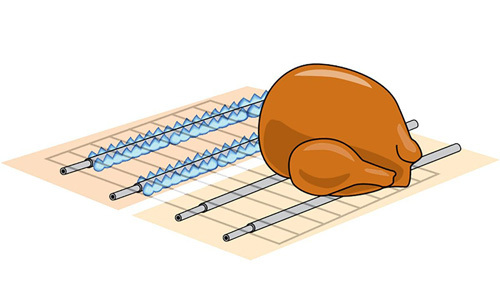

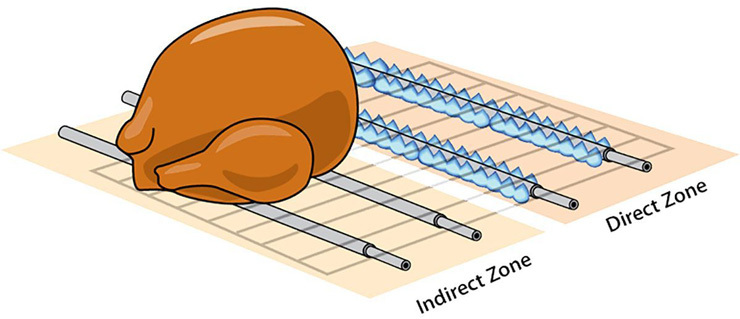

Grills

Cooking on an outdoor grill is one of the most delicious and healthy ways to prepare meals. Natural gas grills are not only fun but also offer a wide range of cooking possibilities for both home chefs and commercial kitchens. One of the biggest advantages of having a gas grill is the ability to choose between direct and indirect grilling. While direct heat is great for searing burgers and vegetables, some dishes benefit from a slower, more even cooking method. Indirect grilling allows you to cook thicker cuts of meat, whole chickens, and even delicate fish with precision and better flavor retention. Indirect grilling is exactly what it sounds like—cooking food away from the direct flame. This method uses radiant heat to slowly cook your meal, preserving moisture and enhancing taste. It often requires additional tools such as timers, secondary racks, and temperature gauges to ensure perfect results every time. Many chefs, especially those in catering or restaurant settings, prefer pedestal grills because they’re space-efficient and easy to use. The AEI Legacy series has become a popular choice for its durability and performance, making it ideal for both residential and commercial use. While direct grilling gives that classic char and smoky flavor, it’s not always the best option for thicker cuts of meat. These items need time to cook through without burning on the outside. Indirect grilling offers a more refined approach, allowing you to achieve tender, juicy results that are hard to replicate in an oven. By mastering indirect grilling techniques, you can expand your menu and impress guests with restaurant-quality dishes right in your backyard. Whether you're hosting a dinner party or running a food business, this method can elevate your outdoor cooking game significantly. Before diving into the methods, it's important to note that indirect grilling works best on natural gas grills, like the AEI Legacy line. Charcoal grills are not designed for this technique and can be difficult to manage effectively. Indirect grilling isn’t just about convenience—it’s about unlocking new flavors and textures. With the right tools and techniques, you can cook everything from ribs to whole fish with ease and confidence. One of the biggest trends in natural gas grills today is the inclusion of infrared rotisseries. As more people look for convenience, these features have become increasingly popular among both home cooks and professional chefs. Other trending accessories include side shelves for extra prep space, built-in timers, and smart grilling systems. These additions make it easier than ever to master techniques like indirect grilling and keep your meals perfectly cooked every time. The AEI Legacy series continues to lead the way with its innovative design and versatility. Whether you're a seasoned chef or a backyard BBQ enthusiast, there’s something for everyone in the world of modern outdoor grilling. Want more information? Have a question? Contact us today, and we will be happy to help! Air cooled heating system, air cooled induction heating equipment, air cooled induction heating power supply, air cooled induction heating machine Ningbo Dedao Electronic Technology Co., Ltd , https://www.nbdedao.comIndirect Grilling Techniques Enhance Outdoor Cooking and Flavor

Why Indirect Grilling Works

Three Key Indirect Grilling Techniques

Trending Outdoor Grill Options

Go Back To Blog

The air-cooled induction heating system is an efficient heating solution that combines induction heating technology and the concept of air-cooled heat dissipation. It is mainly used in industrial applications that require fast and precise heating. At the same time, it effectively manages the heat generated during the heating process through forced air cooling, ensuring the stability and safety of the system. This system has a wide range of applications in industries such as metal processing, heat treatment, and electronic manufacturing.

working principle

The air-cooled induction heating system utilizes the principle of electromagnetic induction to generate a changing magnetic field in the induction coil through high-frequency or medium frequency current. This magnetic field excites eddy currents in the target metal workpiece, thereby generating thermal energy and achieving rapid heating of the workpiece. In order to prevent the induction coil and other key components from overheating under high-intensity operation, the system is equipped with a strong air cooling mechanism, which uses fans or blowers to forcibly guide air circulation, take away the heat generated by the equipment, and maintain the temperature of the entire system within a safe range.

system composition

Induction heating unit: comprising an induction coil and a power supply, generating high-frequency or medium frequency magnetic fields.

Air cooling system: composed of a fan or blower, which forces air circulation.

Control system: Adjust heating parameters, monitor temperature, and protect the system from overload.

Workpiece support: Ensure the stability of the workpiece during the heating process.

Advantages and Characteristics

Fast heating: High frequency or medium frequency induction heating, short heating time, high efficiency.

Precise control: By adjusting frequency and power, accurate control of heating depth and temperature can be achieved.

Good safety: The air-cooled design reduces system temperature, prolongs service life, and reduces safety hazards.

Environmental protection and energy conservation: Compared to traditional heating methods, it has lower energy consumption and no emissions of exhaust gas and wastewater.

Flexible application: Suitable for workpieces of various metal materials and sizes.

Application scenarios

Metal heat treatment: surface quenching, welding preparation, hot assembly, etc.

Electronic manufacturing: component soldering on PCB boards, semiconductor packaging.

Automotive industry: Heating of components such as bearings, connecting rods, gears, etc.

Aerospace: Heat treatment of special alloy materials.

Jewelry: Processing and repairing of precious metal products.

Development Trends

With the improvement of industrial automation level, air-cooled induction heating systems are developing towards integration and intelligence, adopting more advanced artificial intelligence and Internet of Things technology to achieve remote monitoring and automation control, improving production efficiency and safety. Meanwhile, customized solutions tailored to specific industries are constantly emerging to meet the diverse needs of the market.