Industrial operations face many challenges on any job site. One of the most critical is ensuring that the equipment and gearboxes supporting their work can endure harsh conditions while maintaining peak efficiency.

Enhancing gearbox performance requires a comprehensive approach tailored to specific applications. Some tasks can be handled independently, while others are best left to experienced Falk technicians. Regardless of the path you choose, here’s how our team helps extend the life of your speed reducer and boost efficiency.

Choose the Right Gearbox for Your Needs

Falk offers a wide range of gearboxes with various configurations, sizes, and specifications. The right choice directly affects energy use and operating costs. Understanding whether you need a right-angle or parallel gear set is just the start. You should also consider:

- Operating speed and torque

- Efficiency and power rating

- Load capacity

- Environmental conditions

- Precision and control

- Mounting and space requirements

Choosing the correct gearbox can be tricky. That’s why we recommend consulting a Falk technician to find the best match for your needs.

Regular Inspections Are Key

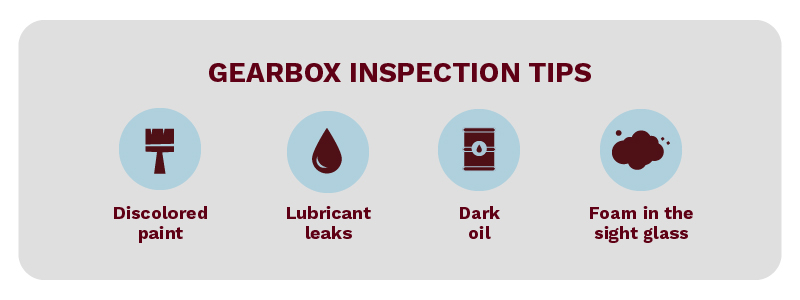

Monitoring for wear and keeping your workspace clean is essential for maintaining efficiency. Damaged parts should be replaced immediately using spare components if available. Here are some inspection tips:

- Look for signs of overheating like discolored paint, dark oil, or foam in the sight glass.

- Check for gear wear such as brinelling, spalling, and misalignment.

- Inspect for contamination or lubricant leaks.

- Perform vibration tests to detect unusual noises or changes in function.

Stick to Preventive Maintenance Schedules

Even with regular care, industrial gear drives require professional attention. Over time, they experience stress and wear, making expert servicing crucial. Neglecting maintenance can lead to costly breakdowns and safety risks. That’s why having a Falk technician on call is important.

Monitor and Maintain Oil Levels

Proper lubrication keeps gear drives running smoothly and efficiently. It reduces friction and prevents contaminants from damaging internal components. We recommend checking that the lubricant meets manufacturer specs and performing an oil analysis for:

- Water content

- Sediment

- ISO viscosity rating

- Acid number

- Other contaminants

Avoid Overloading the Gearbox

Exceeding the rated load can damage the gearbox. Motor power and speed determine torque limits, so changes to either factor can impact performance. Devices like belts and chains mounted on the input shaft can create overhung loads, which may harm the shaft and bearings. Knowing your service factor will help prevent these issues.

Count on Our Experts for Optimal Performance

Ensuring top-notch gearbox performance boosts efficiency and reduces downtime. Our team of skilled Falk technicians provides customized repair and maintenance services. From proper lubrication to component replacement, we follow industry standards to keep your gearboxes running longer.

Contact us today for a personalized solution to meet your gearbox needs.