5 minute read

|

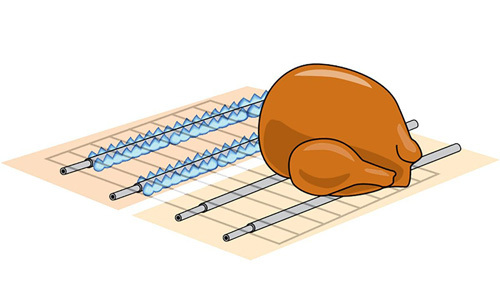

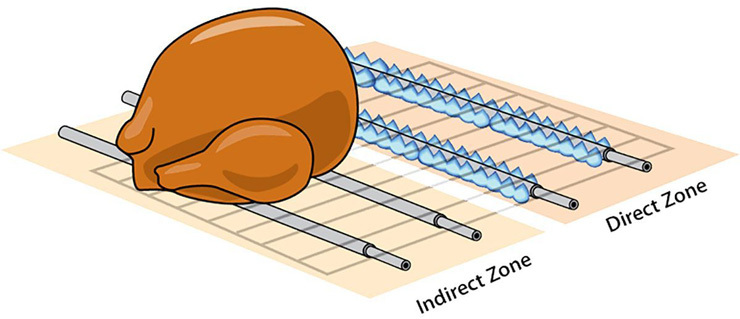

Grills

Grilling outdoors is one of the most delicious and healthy ways to prepare food. Natural gas grills are not only fun but also offer a wide range of cooking possibilities for both home chefs and professional kitchens. One of the best features of modern grills is the ability to use either direct or indirect grilling methods. This flexibility allows for cooking everything from thick steaks and whole chickens to fresh vegetables in a more refined way. While direct grilling is great for burgers and other quick-cook items, some dishes benefit from a slower, more controlled approach. Indirect grilling means placing your food away from the direct heat source and letting it cook slowly. This method often requires accessories like a timer, secondary rack, or even a rotisserie. It’s especially popular among caterers and restaurants that want to expand their outdoor menu options. Many chefs prefer pedestal grills because they’re efficient, space-saving, and perfect for both residential and commercial use. The AEI Legacy series, for example, has become a top choice for its quality and versatility. While direct grilling is great for searing and locking in juices, thicker cuts of meat or delicate vegetables need a gentler touch. That's where indirect grilling shines. It brings out rich flavors, preserves moisture, and gives you more control over how your food turns out. By using indirect techniques with the right accessories, you can take your outdoor cooking to the next level. Whether you're hosting a backyard BBQ or running a food business, this method opens up new possibilities for your menu. To get started, it's important to know that indirect grilling works best on natural gas grills, like those in the AEI Legacy line. Charcoal grills are not designed for this technique and can be difficult to manage. Here are three common indirect grilling techniques: Indirect grilling is more than just a technique—it's a game-changer. It helps you preserve smoky flavors, create caramelized textures, and cook thicker cuts of meat with precision. Whether you're a seasoned chef or a weekend griller, this method is worth mastering. One of the biggest trends in natural gas grills is the inclusion of infrared rotisseries. These make it easier to cook whole chickens and other large pieces of meat quickly and evenly. As convenience becomes more important, many homeowners and businesses are adding these features to their grills. Other popular additions include extra side shelves for more prep space, digital timers, and smart grilling systems. These tools help make indirect grilling more precise and less time-consuming. The AEI Legacy series offers a variety of customizable options, so you can upgrade your grill as needed. With the right accessories and techniques, your outdoor cooking experience can reach new heights. Want more information? Have a question? Contact us today, and we will be happy to help! Open/close induction coil, induction heating coil, heating coil, quenching coil Ningbo Dedao Electronic Technology Co., Ltd , https://www.nbdedao.comIndirect Grilling Techniques Enhance Outdoor Cooking Experience and Flavor

Why Indirect Grilling Works

How to Master Indirect Grilling

Trending Outdoor Grill Features

Go Back To Blog

Induction heating coil is a device that uses the principle of electromagnetic induction for induction heating. It is commonly used for heating metal materials, such as in industrial processes such as welding, heat treatment, and melting. The working principle is to generate eddy currents (induced currents) inside the heated metal through the alternating magnetic field generated when alternating current flows through the coil. This eddy current in turn generates its own magnetic field and interacts with the original magnetic field, causing heat to be generated inside the metal and achieving heating.

The design and application of induction heating coils have the following key points:

1. Induction coil structure: The coil is usually made of conductive materials such as copper or aluminum, and its shape and size are designed according to specific application requirements. It can be circular, square, or other shapes. The number of turns, diameter, and wire diameter of the coil can affect heating efficiency and power output.

2. Frequency selection: The efficiency and effectiveness of induction heating are related to the frequency of use. High frequency (several kilohertz to tens of megahertz) is suitable for rapid heating of thin-walled components, while low frequency (several hundred hertz to several thousand hertz) is more suitable for uniform heating of thick walled components. According to the frequency of induction heating equipment, it can be divided into high-frequency induction coils, intermediate frequency induction coils, ultra-high frequency induction coils, and ultrasonic induction coils

3. Power control: By adjusting the current input to the induction coil, the heating power and temperature can be controlled. This function is usually achieved using electronic devices such as thyristors and inverters.

4. Induction cooling system: In order to protect the heating area from overheating, an induction cooling system may be required, especially during continuous heating operations.

5. Safety measures: Induction heating equipment must be equipped with effective safety measures, including preventing electric shock, avoiding spark splashing, and ensuring good ventilation in the operating environment.

Induction heating coils are widely used in various fields such as metal processing, automotive manufacturing, aerospace, medical equipment, etc., and are one of the indispensable high-efficiency heating technologies in modern industry.