JIANGMEN PRO-TAYLOR REFRIGERATION CO., LTD. , https://www.protaylor.com

# Modern Industry and the UT Drone

In every corner of the globe, industries follow their own specific rules and regulations to ensure the safety of personnel, the environment, and the equipment being utilized. These guidelines are established by a variety of organizations ranging from government bodies and national agencies to international classification societies and global institutions.

## The Challenge of Inspection Data Collection

An inspection demands reliable data to succeed—but obtaining this data isn't always straightforward. For assets such as ships or storage tanks, gathering information for an inspection can be particularly challenging, especially in situations where safety concerns arise. As a result, alternative methods of access are becoming increasingly popular, with drones playing a significant role. They can reach previously inaccessible areas—whether at height, in confined spaces, or even underground—to collect crucial data that is vital for inspections but otherwise unreachable. This is precisely where the **UT drone** comes into play.

*Caption: Every industry enforces rigorous safety protocols. Sectors like shipping rely heavily on ultrasonic testing equipment to assess the condition of assets.*

## What is a UT Drone?

A **UT drone**, or unmanned aerial vehicle (UAV), is specifically designed to perform ultrasonic thickness measurements. This technology allows for the collection of ultrasonic thickness (UT) data from hard-to-reach locations such as chimneys, ballast tanks, or flue ducts.

A **UT drone** is integral to **drone-enabled non-destructive testing**, streamlining the inspection process. By providing safer access to assets, drones can significantly enhance inspection efficiency and improve overall asset management.

*Caption: The Elios 3 is an excellent example of a UT drone.*

## How Does a UT Drone Operate?

Traditional ultrasonic testing involves placing an ultrasonic testing device (probe or gauge) against the test surface and transmitting sound waves through the material. The reflection of these waves is measured by the probe to determine the thickness of the material under test.

For most conventional drones, taking UT measurements is extremely difficult since they aren't typically built to make contact with surfaces or remain stationary for extended periods. This is why **UT drones** are uniquely specialized and engineered to function in environments beyond the capabilities of standard drones.

*Caption: A UT drone carries a special payload equipped with an ultrasonic thickness measurement probe.*

**UT drones** approach a measurement point, place their probe against the surface, and apply a couplant solution to optimize sound transmission from the probe to the material. After this, the UT measurement is taken. Some **UT drones** allow for adjustments to gain and gates during the measurement based on the material's properties. Once the measurement is complete, the drone can detach and move to another location.

### How Many Measurements Can a UT Drone Take?

The number of measurements a **UT drone** can perform depends on several factors including the drone’s flight time, the amount of couplant it can carry, and the skill level of the operator. For instance, the Elios 3 UT drone can complete up to 40 UT measurements per flight.

## Benefits of a UT Drone

As part of drone-enabled non-destructive testing, a **UT drone** offers numerous advantages for improving the safety, efficiency, and accessibility of traditional UT inspections. These benefits ultimately reduce the costs associated with drone UT inspections.

### SAFETY

Using a **UT drone** removes humans from potentially hazardous situations during inspections. Some measurement points are either at heights or in confined spaces, requiring special permits and safety protocols to access. Finding certified UT inspectors who are also trained in rope access can be challenging, creating a high demand for skilled professionals to ensure inspections are conducted safely.

Alternatively, **UT drones** can navigate confined spaces as small as 50x50 cm (20x20 inches), collecting dozens of measurements per flight. This eliminates risks associated with confined spaces, such as toxic gases, suffocation, and drowning. Similarly, a **UT drone** can access high-risk areas like chimney stacks or the upper portions of ship hulls, which traditionally require scaffolding or rope access. In some cases, such as flue duct inspections, regulations require exit points at both ends for human entry, which might involve removing or opening parts of the duct like fan casings. A **UT drone**, however, can enter and exit without the need for human entry, minimizing downtime during inspections.

*Caption: A UT drone can inspect confined spaces like this tank without exposing personnel.*

### EFFICIENCY

A **UT drone** inspection can be completed in under an hour. These drones can be deployed within minutes of arriving on-site. The operator can guide the drone beyond the line of sight using its high-definition camera—and some **UT drones** even offer real-time LiDAR scans, providing a 3D map of the surrounding area.

Moreover, a drone can swiftly move between measurement points, even if they're far apart. This is much faster than moving scaffolding or adjusting rope access technicians between locations. Similarly, drones are quicker than mobile elevated work platforms (MEWPs), capable of flying both indoors and outdoors without limitations on height or breadth.

The efficiency of UT inspections using drones is further enhanced by the recording process. Previously, UT measurements were recorded by rope access technicians shouting values down to someone on the ground, which didn't clearly indicate the exact location of the measurement point and had a high potential for error. Some inspectors wrote values directly on the asset in chalk, but this method is not weather-resistant and can be unclear for future inspectors.

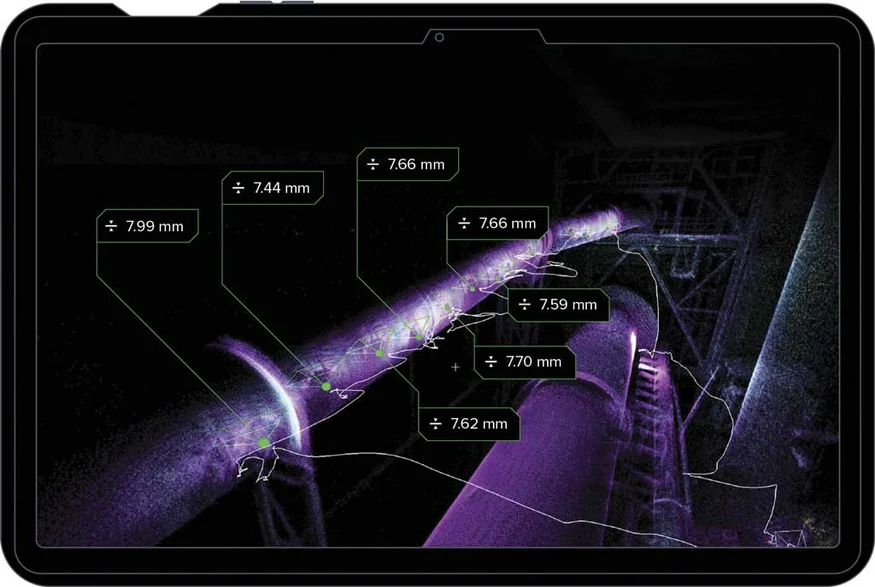

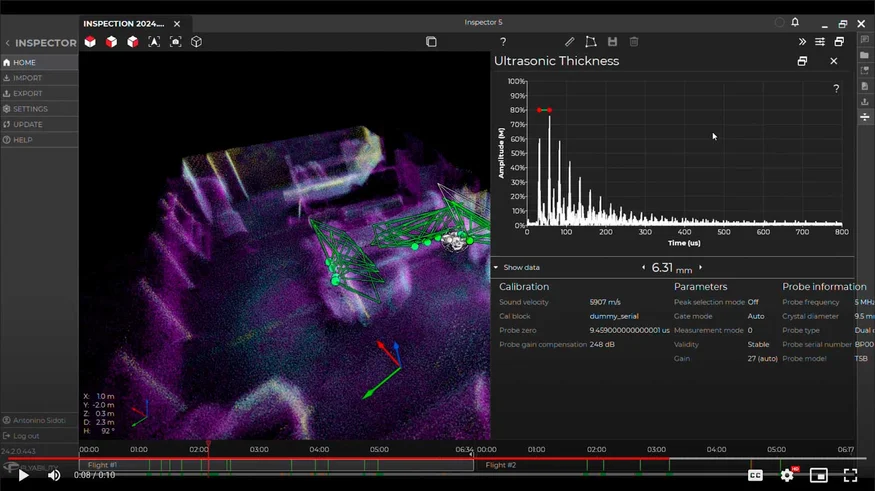

In contrast, a **UT drone** can tag the location of each measurement point, making it simple to identify areas with higher corrosion or degradation rates and dispatch maintenance teams to those precise locations. When these measurement points are tagged within a 3D scan, as with the Elios 3 UT drone, a digital record of the asset is automatically generated, allowing for easy updates over time and tracking of changes.

*Caption: Here are ultrasonic thickness measurements tagged by a UT drone during flight.*

With a **UT drone**, the entire asset management process is streamlined, extending the lifespan of assets through improved management practices.

### ACCESS

A **UT drone** can reach places that traditional methods cannot, whether confined spaces, inside stacks, or even within machinery. These UAVs enable drone-enabled non-destructive testing in ways never before possible. Certain **UT drones** can even fly in areas without GPS, easily accessing underground or confined spaces.

This enhanced access and ease of ultrasonic testing with a UT drone also means inspections can be performed more frequently. When a **UT drone** can take measurements in minutes at heights where scaffolding would take over a day to install/remove, it becomes simpler to conduct inspections more regularly. More frequent UT inspections help identify issues early and provide a more current overview of an asset's condition. **UT drones** promote optimal asset management by making it easier to gather critical data without prolonged downtime or higher costs.

*Caption: A UT drone can explore complex environments and gather critical data that was previously unavailable.*

## UT Drone Case Studies

### Saving $15,000 in Ship Hull Inspections

The Elios 3 UT was employed for a periodic survey of cargo oil tanks on a mid-sized ship. Each cargo tank required a close visual inspection and UT measurements. Normally, this would necessitate scaffolding and a team of 16+ people to access all measurement and survey areas. Using the Elios 3, all measurements were collected with the UT drone.

*Caption: An example point cloud with the Elios 3 UT payload showing spot measurements.*

Discover this UT drone for ship surveys.

### Drone-Assisted Stack Inspection

A stack at a power generation facility needed an inspection. Insulation on the exterior made it difficult to inspect, and the site’s location in Northern Canada added weather-related challenges. The Elios 3 UT drone offered an ideal solution, flying inside the stack where there was no insulation to gather measurements, eliminating the need to remove insulation or use scaffolding.

*Caption: Thanks to the Elios 3's camera, it is possible to complete UT inspections beyond the visual line of sight. The Cockpit app can also be used to manually adjust the gain and gates.*

Read the full UT stack inspection case study.

### Flue Duct and Silo UT Measurements

At a cement plant in Germany, an inspection team sought to determine the viability of using a UT drone. They found that the Elios 3 UT could inspect standard assets like flue ducts and silos without the need for scaffolding or disrupting operations, providing easy access to assets typically difficult to reach.

*Caption: The Elios 3 and UT payload successfully navigated the bends and dust-filled environment inside the flue duct.*

Discover the Elios 3 UT for cement plant inspections.

---

This innovative technology is revolutionizing the way industries approach inspections, making them safer, more efficient, and more accessible.