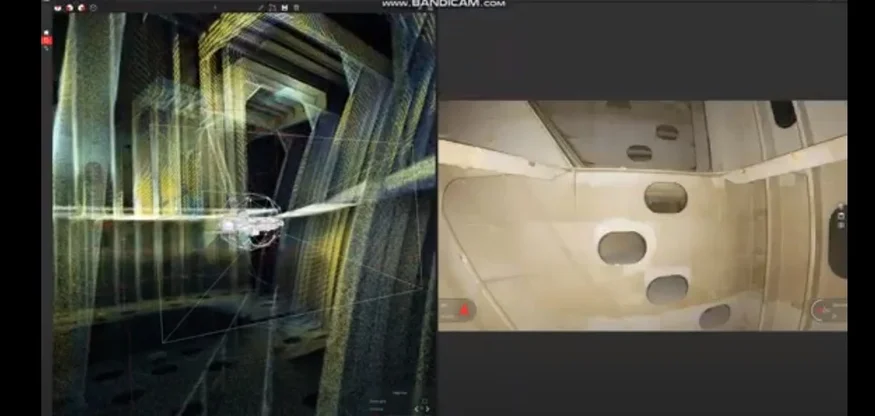

C-Bird used the Elios 3 for a hull inspection of a cargo ship, achieving results that were safer, faster, and more efficient than ever before. SAFETY: By using the Elios 3, C-Bird eliminated the need for scaffolding in cargo tanks, saving approximately 10,000 hours of work at height in confined spaces. COST SAVINGS: Replacing scaffolding with the Elios 3 saved around $1 million during the vessel survey, along with significant time and logistics savings. ENVIRONMENTAL BENEFITS: Using a drone instead of rafting avoids creating large volumes of oil-contaminated water, which would otherwise require costly treatment and disposal. DATA QUALITY: The onboard LiDAR on the Elios 3 enabled precise data localization and easy sharing of findings with all stakeholders, improving decision-making. Over 90% of the world’s cargo vessels are subject to the IACS Common Structural Rules (CSR), which set strict standards for design, construction, and maintenance. These rules ensure that vessels meet high safety and structural integrity requirements. To maintain their classification, ships must undergo regular hull surveys, especially after 5 years of operation. Crude oil tankers face particularly challenging inspections due to the limited access to critical areas inside their cargo oil tanks (COT). Traditional methods like scaffolding or rafting can be dangerous, time-consuming, and costly. The scale of a cargo tank is massive—scaffolding can rise tens of meters, making detailed inspections difficult and risky. As ships age, the complexity and cost of these inspections increase. For vessels over 15–20 years old, the costs of scaffolding alone can exceed $1 million, making it a major portion of the overall project budget. Building scaffolding not only increases safety risks for workers but also poses operational hazards, such as foreign objects left in the tanks that could damage cargo pumps. Rafting, on the other hand, introduces environmental concerns due to the large volume of contaminated water involved. A US-based oil tanker operator needed to conduct a No. 4 Special Periodical Survey on one of its 250-meter vessels, classed by the American Bureau of Shipping (ABS). The ship was undergoing dry docking in Southeast Asia for class renewal and other maintenance work. The company had been using C-Bird's services for several years, leveraging the Elios 2 for close-up inspections. This collaboration significantly reduced the need for scaffolding during previous surveys, making the Elios 3 an attractive next step. The goal was to perform a hull survey using the Elios 3 without any personnel entering the cargo tanks, minimizing risk while collecting all necessary data. Initially, they considered using a remotely operated vehicle (ROV), but C-Bird's experience with the Elios drones made it clear that the drone was the better option. C-Bird pilot Malcolm Connolly opted for the Elios 3, drawn by its 3D Live Map feature, which allowed him to navigate the dark and complex environment without seeing the drone directly. He also tested the new UT payload for ultrasonic thickness measurements. Malcolm guides the drone through the empty space during the inspection. The Elios 3 was flown into the cargo tanks without any human entry, capturing 4K video footage and real-time 3D LiDAR scans of the entire structure. The data was then processed using Inspector 4, allowing for a full 3D reconstruction of the inspected area. This process ensured complete coverage, eliminating uncertainty about what had been surveyed and where anomalies were located. The result was a highly accurate and reliable dataset that met all classification requirements. The Elios 3 combines LiDAR data with visual feed for precise inspections. The Elios 3’s 3D Live Map helped C-Bird cover all required areas in the cargo tanks from the safety of the ship’s deck. It eliminated the need for manual equipment handling, reduced the risk of dropped objects, and cut down on setup time for each tank. Malcolm Connolly, CEO of C-Bird, emphasized the benefits of the Elios 3: “The 3D laser scan gives us precise data localization, bringing us closer to true risk-based asset management and automation. With this level of accuracy, we can repeat surveys, track changes, and even predict degradation using machine learning.†He highlighted several key advantages, including full coverage, improved safety, cost savings, and the ability to operate in extreme temperatures up to 45°C. Thanks to the Elios 3, C-Bird completed a safer, faster, and more efficient hull inspection, avoiding the need for scaffolding and saving over 10,000 hours of working at height. The simplified logistics, reduced environmental impact, and effectiveness compared to traditional methods made the drone a game-changer for the client. The Elios 3 provided enough data for successful class renewal, proving that drone technology is evolving to meet the needs of the maritime industry. This case study shows how advanced drone solutions are reshaping the future of inspections, making them smarter, safer, and more sustainable. Neodymium Cup Magnets,Strong Neodymium Bar Magnets,Super Strong Neodymium Magnet,Strong Neodymium Magnet Dongguan Zhenglong Magnet Co., Ltd , https://www.zlmagent.comRemote Hull Inspection Saves $1 Million With The Elios 3

Key Benefits At A Glance

Seeking a Safer and More Efficient Inspection Method

How the Elios 3 Transformed the Inspection Process

Why the Elios 3 Is a Game-Changer for Maritime Inspections

Transforming Hull Inspections for the Future